Shelling

Shredding

systems

“Our goal is to build each day, more and more efficient and reliable products, to impress the customer with the performance of our machines.”Antonio Ferrara

Shelling s.r.l.

Engineering and experience at the service of reliability

WHY CHOOSE SHELLING

High performances and low power consumption

Our company

Shelling is an Italian company based in Robassomero (TO).

It produces shredders on the basis of a thirty years experience combined with the most advanced techniques of engineering and manufacturing.

It is characterized by attention to details in its products and carries out its research focusing them on the needs of customers, not only in technical terms but with the aim to minimize the variable costs associated with the use of the machines.

APPLICATIONS AND SECTORS

Metal, Rubber, Food, Biomass, Pharmaceutical

METAL

GRINDING

CANS

Grinding, refining and cleaning of iron and aluminum containers and cans from RSU. Quality proler ready for the foundry

METAL

ELECTRIC

ENGINES DISPOSAL

Both for the grinding of electric motors coming from R.A.E.E. than for those of industrial type, we supply complete

ready to use for the perfect valorization of the copper and the metals in output

METAL

R.A.E.E.

DISPOSAL

R.A.E.E. are electronic and electrical equipment waste and represent the fastest growing global waste category with a growth rate of 3-5% per year, three times higher than normal waste.

METAL

RADIATOR

RECYCLING

The shredding implants specific for radiators are the most advanced, always obtaining maximum gain from all the metals in output.

RUBBER

CRANKCASE

DISPOSAL

In the grinding, separation and enhancement of the aluminum crankcase, Shelling plants guarantee highest quality results to allow the exploitation of this type of waste and thus reintroduce it into the production circle through the foundry.

FOOD INDUSTRY

SLAUGHTER

WASTE

Disposal of animal entrails, treatment, collection and recycling of slaughter waste. Our newly designed plant can be defined as an industrial shredder for slaughter waste, a biological waste shredder or an organic waste shredder and carcass.

BIOMASS

BIOMASS

DISPOSAL

Our newly designed plant can in all respects be defined as a professional branch shredder: a recent alternative to the classic chipper. This modern biomass grinder is suitable as a branch cutter and as a composting shredder, as well as a corn and wood shredder.

TOTAL GUARANTEE AND RELIABILITY

Our services

AFTER SALES SERVICE

The Shelling provides the customer with efficient after sales service. Skilled technicians with mobile workshops are able to perform all maintenance and repairs also at the customer’s premises. We perform services throughout Europe while maintaining a high degree of readiness and efficiency of the staff.

SPARE PARTS

Shelling The seat is equipped with a fully stocked parts warehouse ready. If the parts were not to be present within the warehouse guarantee celerity in catering for any particular customer of our machines so as to avoid production stops.

HIGH PERFORMANCES AND LOW POWER CONSUMPTION

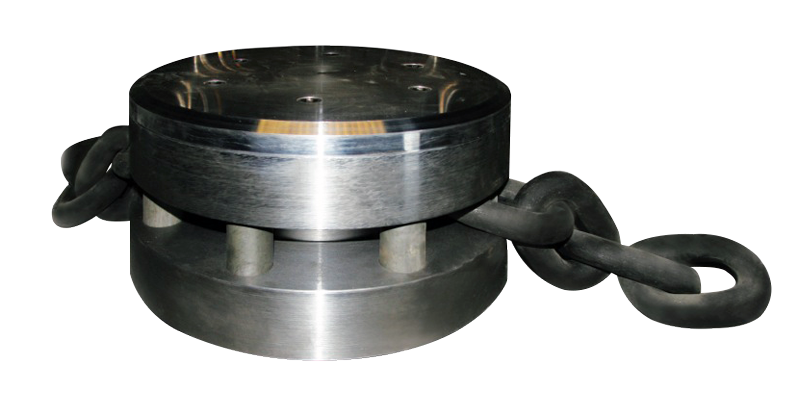

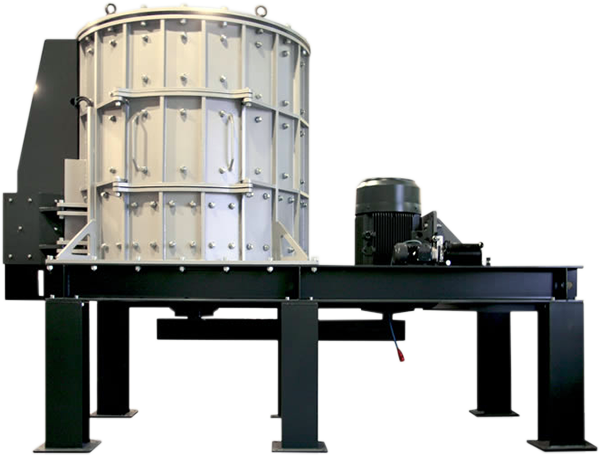

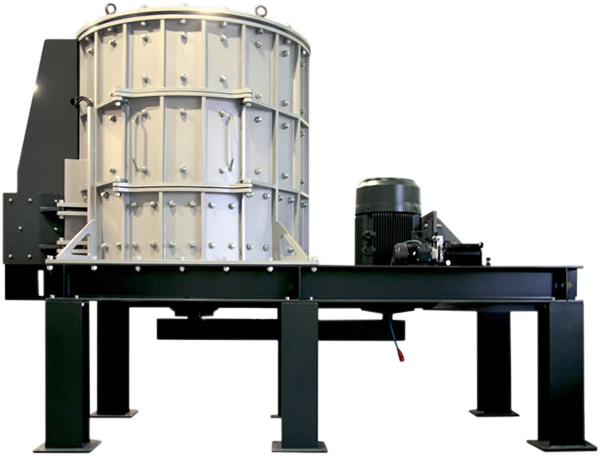

SHELLING MAC

Our products

FOOD AND MASS

MAC 800

Twelve-sided chains grinder to supply with top loading.

Engine power: 45 kW/55 kW

Biomass and slaughter waste

SERIES 1000

Twelve-sided chains grinder to supply with top loading.

Engine power: 55 kW/75 kW

METAL

SERIES 1600

Twelve-sided chains grinder to supply with top loading.

Engine power: 160 kW/200 kW

METAL

SERIES 2000

Twelve-sided chains grinder to supply with top loading.

Engine power: 160 kW/200 kW

High Performances and low power consumption

The MAC is the result of engineering and technical research that arises from the need to build an effective grinder, limiting at most costs and maintenance time.