Shelling

Our products

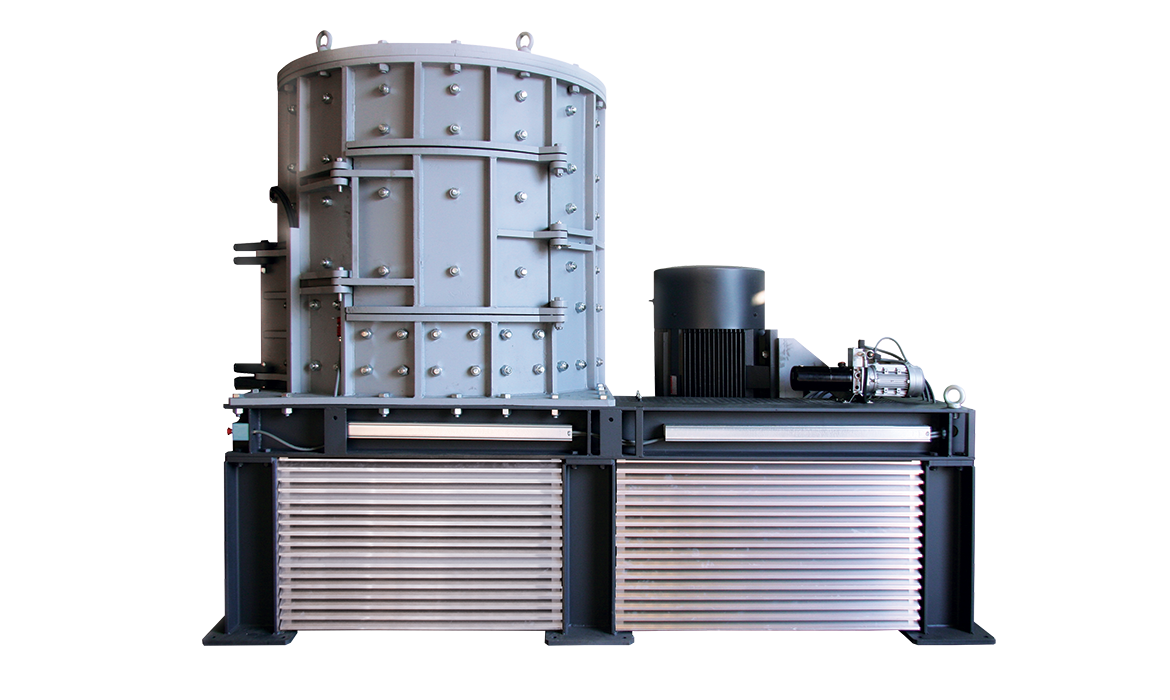

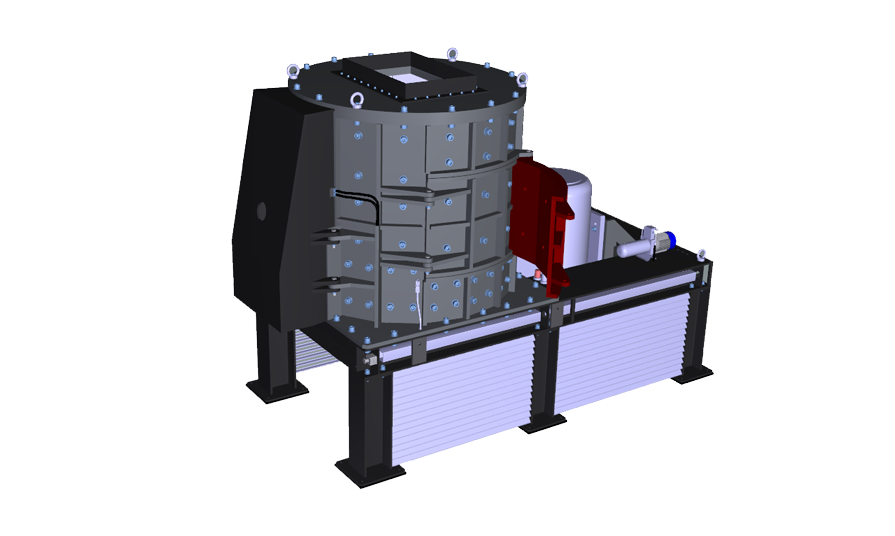

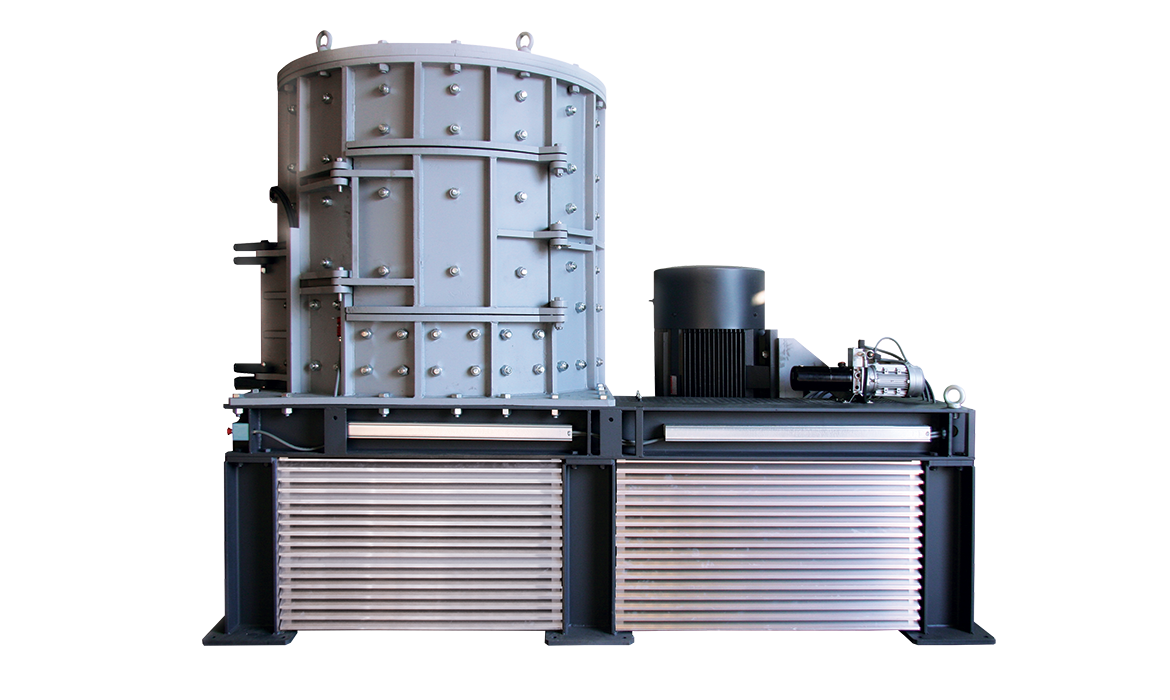

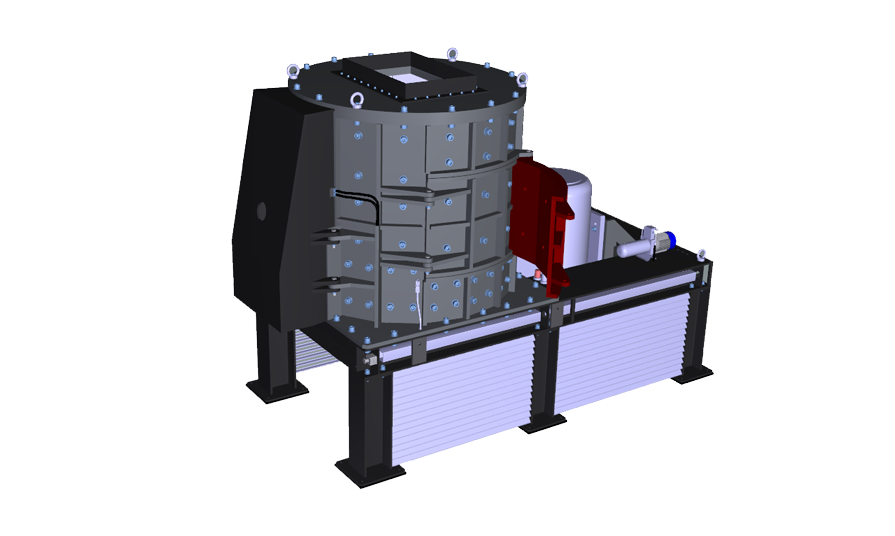

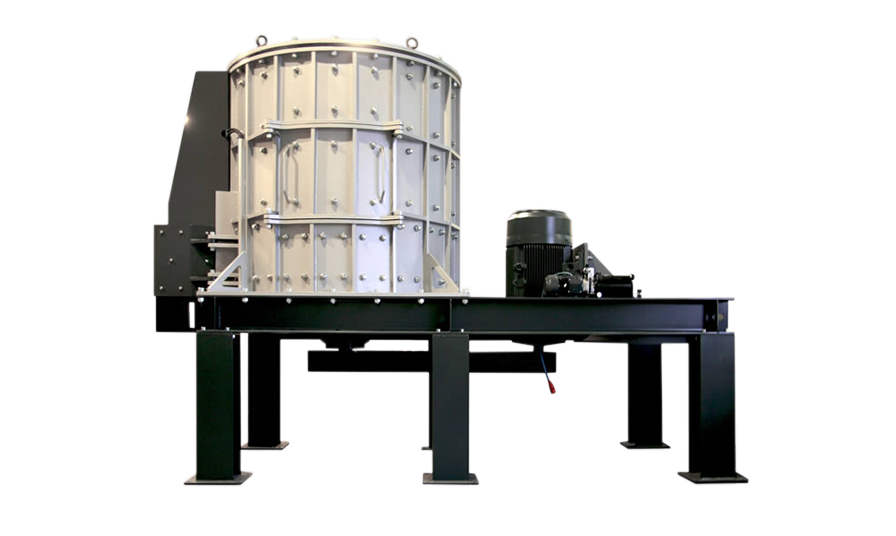

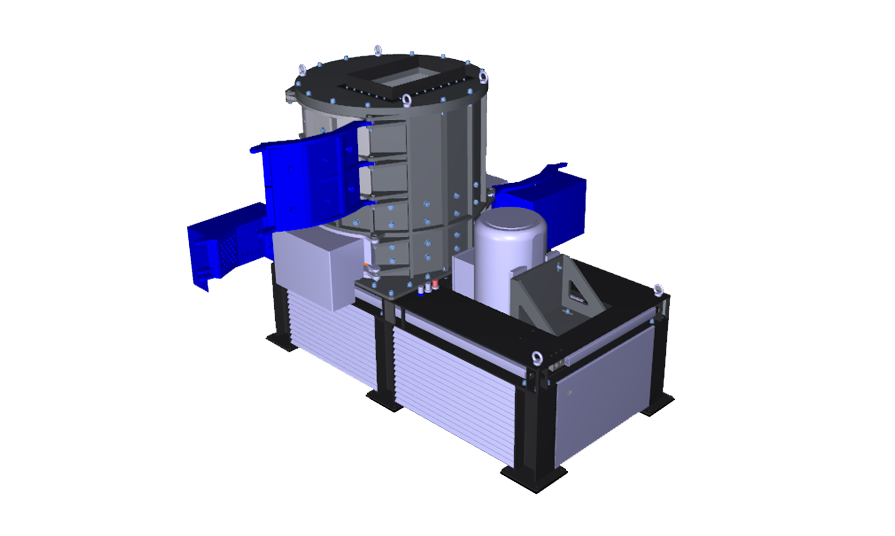

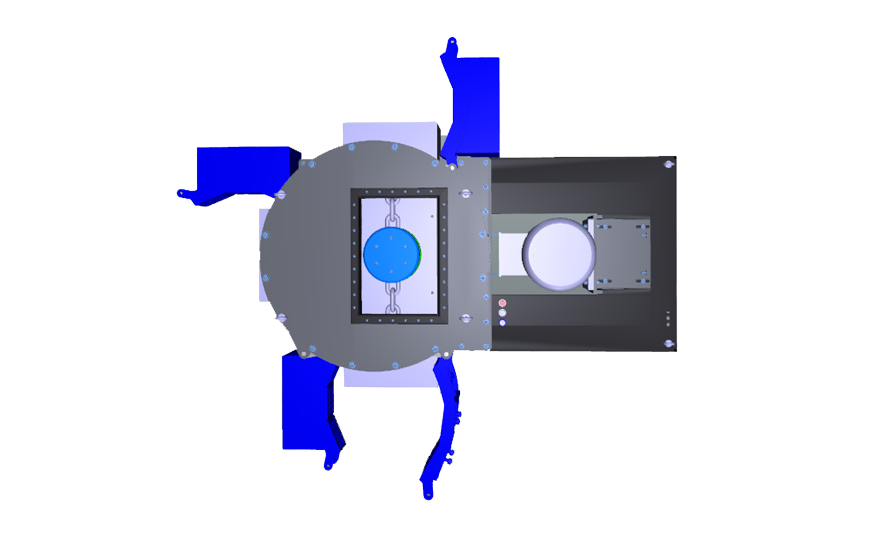

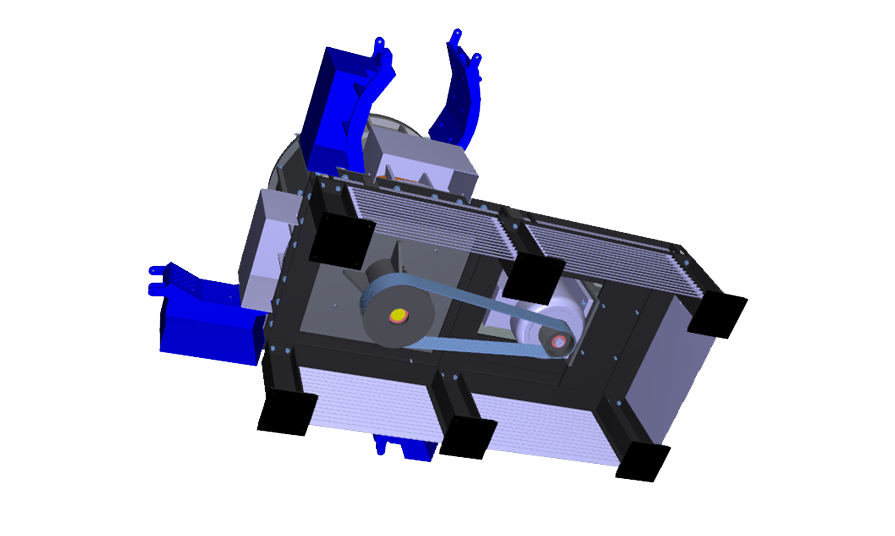

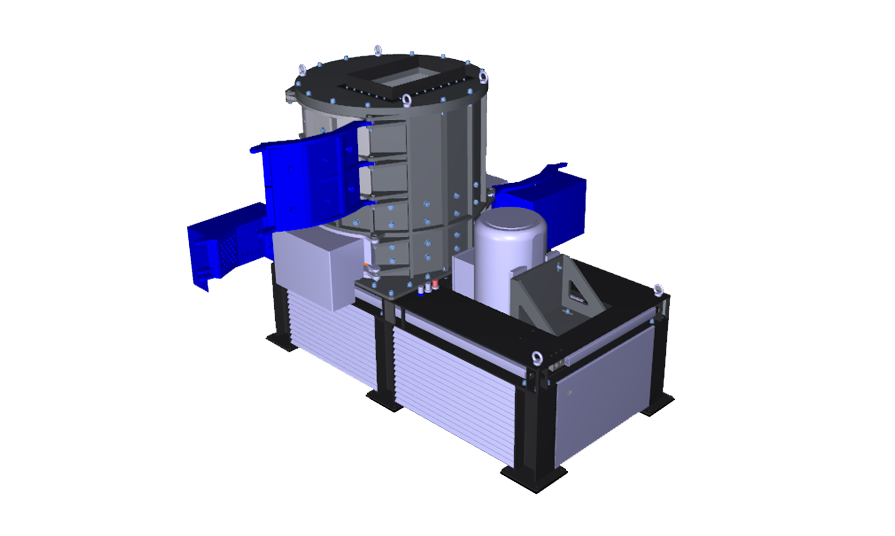

TWELVE-SIDED CHAINS GRINDER

Shelling MAC

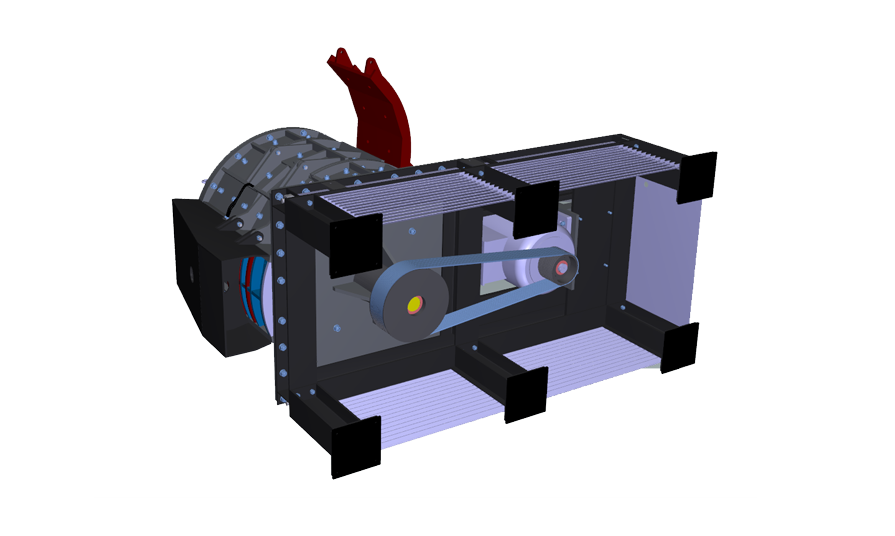

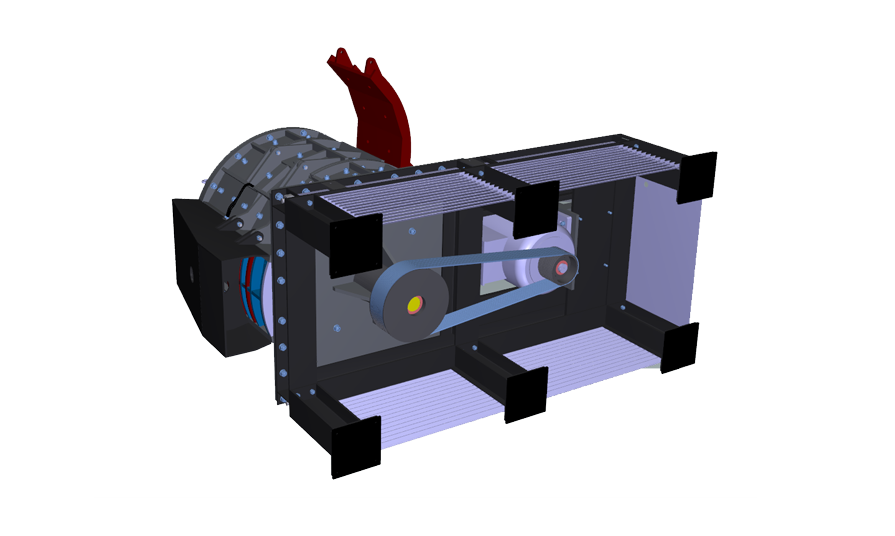

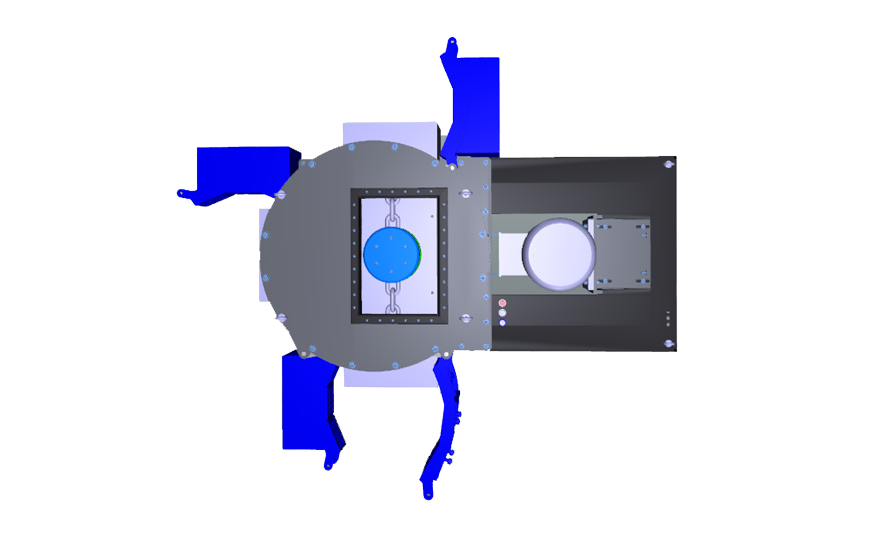

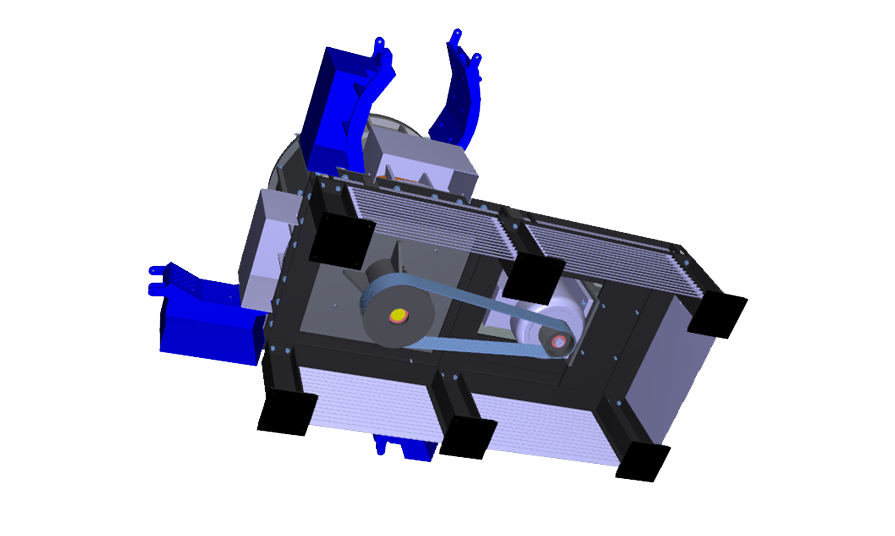

The MAC is a twelve-sided chains grinder to supply with top loading.

Can be loaded with cochleas or conveyor belts through a hopper. The MAC is the result of an engineering and technical research that arises from the need to build an effective grinder, limiting at most costs and maintenance time.

Its high efficiency is based on the principle of the flywheel. The latter exploits the kinetic forces of the same products inserted inside the grinding chamber to be crushed, which are not only disintegrated and decomposed by the tool (chain), but collide with each other thanks to the vortex created, with a consequent increase in the production and minimizing the wear.

| Model | Engine power | Crushing chamber dimensions | Dimensions mx. input material |

| MAC 1000 | 55/75 kW | 1000 X 1000 cm | 600 x 600 mm |

| MAC 1600 | 160/200 kW | 1600 X 1600 cm | 1000 x 1000 mm |

| MAC 2000 | 200/250 kW | 2000 X 2000 cm | 1200 x 1200 mm |

APPLICATIONS

ALUMINUM

.

COPPER

.

BRASS

.

R.A.E.E.

.

REFRIGERATORS

.

BIOMASS SECTOR

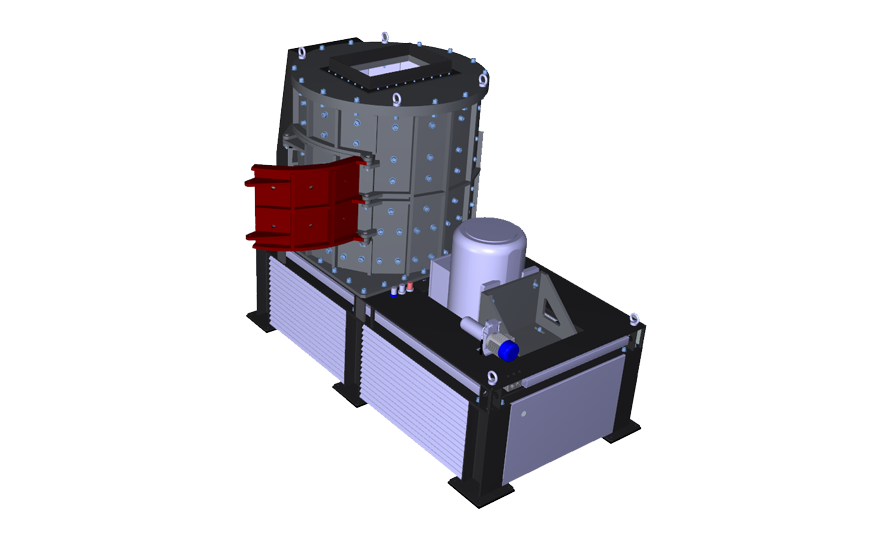

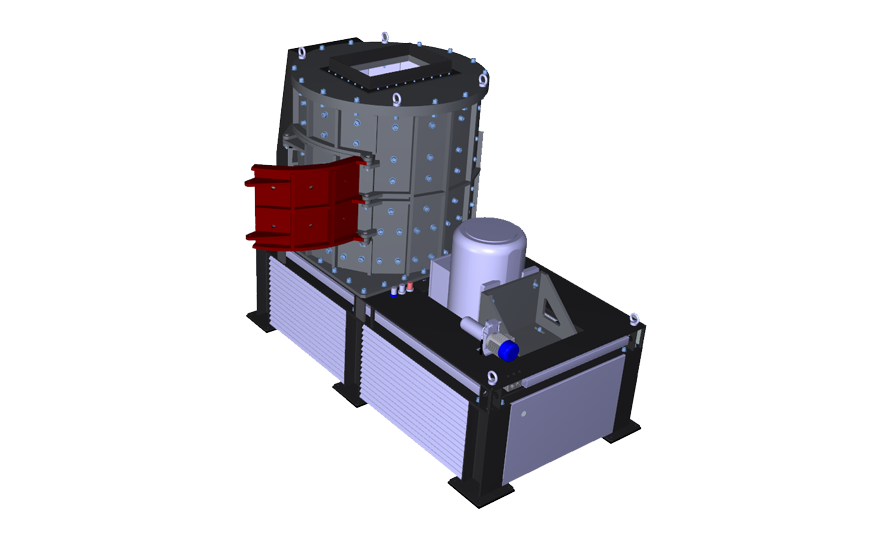

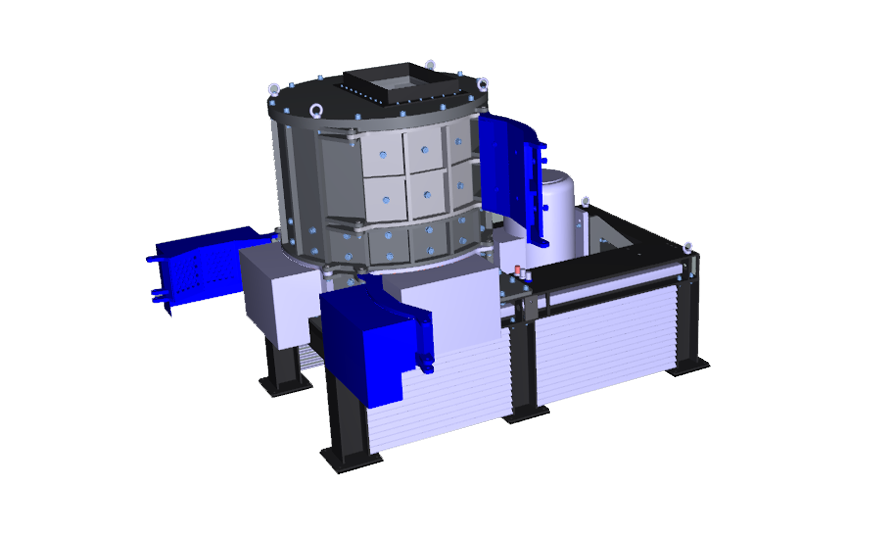

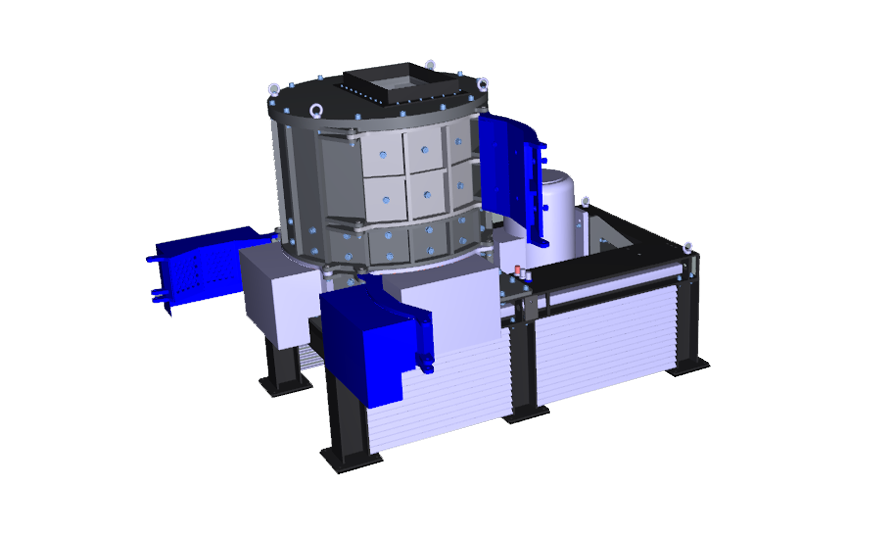

Shelling MAC L.E.

Specially designed for the biomass sector MAC LE has three outlet grids. This choice is dictated by the need to implement to make the production and therefore develop the best relationship between costs and tons broken.

In the field of biomass the main economic benefits are achieved by lowering the costs of fermentation. In addition, improving the digestion of substrates expands the range of products that can be used even with the presence of extraneous components such as ferrous metals that are removed post-crushing.

| Model | Engine power | Crushing chamber dimensions | Dimensions mx. input material |

| MAC L.E. 800 | 45/55 kW | 800 X 800 cm | 500 x 500 mm |

| MAC L.E. 1000 | 55/75 kW | 1000 x 1000 mm | 600 x 600 mm |

| MAC L.E. 1600 | 160/200 kW | 1600 x 1600 mm | 1000 x 1000 mm |

| MAC L.E. 2000 | 200/250 kW | 2000 x 2000 mm | 1200 x 1200 mm |

APPLICATIONS

CORN SILAGE

.

GREEN SILAGE

.

BEETS AND TUBERS

.

STRAW

.

AGRICULTURAL RESIDUES

.

SLAUGHTER WASTE

.

ACCESSORIES

HIGH RELIABILITY

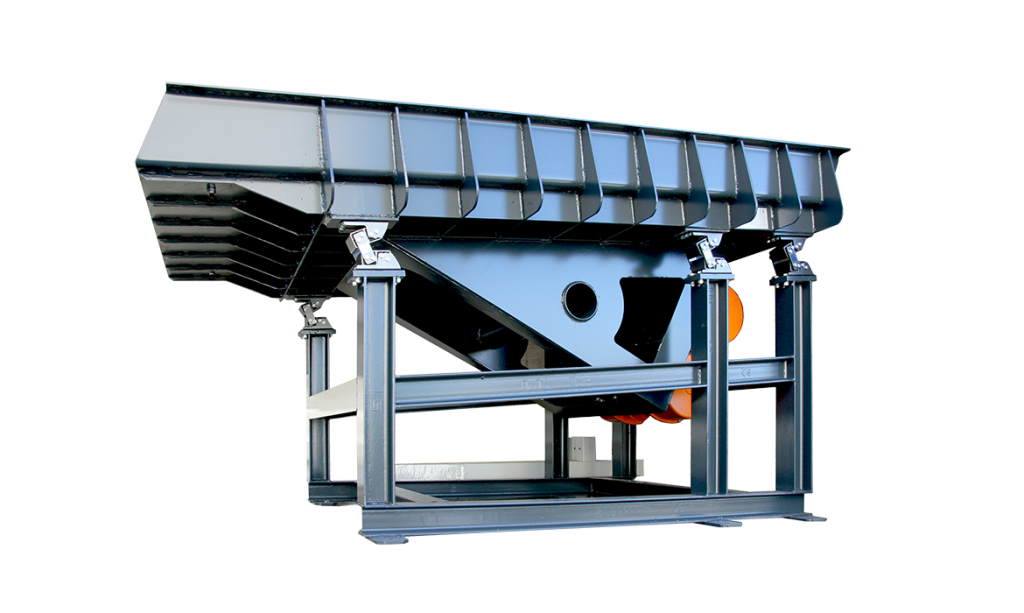

Conveyor

For conveyor belts Shelling was adopted the same attention to detail used for chopping. The studies carried out on conveyors Shelling have been developed to limit the inefficiencies and avoid downtime due to breakage or drawbacks. Reliability is always the first place and that is why they are used only the highest quality components and very efficient.

HIGH RELIABILITY

Channels vibrant

The channels are used primarily in Shelling vibrant output from the grinders. They are produced in different sizes 800 – 1000 – 1500 mm. They are equipped with two vibrating motors. The particularity of this product is the use of a plan in abrasion material to promote durability.